Aluminum Busbars: Lightweight, Efficient, and Cost-Effective Electrical Solutions

Aluminum busbars are an increasingly popular choice for electrical distribution systems due to their lightweight design, excellent conductivity, and cost-effectiveness. Used in everything from power generation facilities to industrial manufacturing plants, aluminum busbars provide a reliable means of conducting electricity while offering several advantages over traditional copper alternatives.

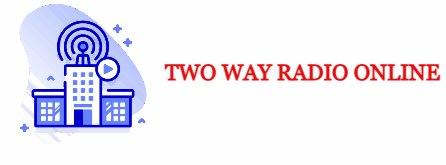

What Are Aluminum Busbars?

An aluminum busbar is a solid strip or bar of aluminum used to conduct electricity within a switchboard, distribution board, substation, or other electrical apparatus. Busbars simplify electrical layouts by allowing multiple circuits to connect to a single, centralized conductor.

Aluminum is widely used in busbar manufacturing because it offers a strong balance of conductivity, weight reduction, and cost savings without compromising performance in most applications.

Advantages of Aluminum Busbars

- Lightweight – Aluminum is about one-third the weight of copper, making installation easier and reducing structural support requirements.

- Cost-effective – Aluminum typically costs less than copper, lowering project budgets without sacrificing quality.

- Corrosion resistance – Naturally forming an oxide layer, aluminum busbars are resistant to corrosion in most environments.

- Excellent conductivity – While slightly less conductive than copper, aluminum still provides efficient power transmission for many electrical applications.

- Recyclable – Aluminum is highly recyclable, making it an environmentally friendly choice.

Common Applications for Aluminum Busbars

Aluminum busbars are versatile and can be found in a variety of industries and applications, including:

- Electrical switchgear and panel boards.

- Renewable energy systems, including solar and wind power installations.

- Industrial manufacturing equipment.

- Power distribution units in commercial buildings.

- Automotive and electric vehicle charging stations.

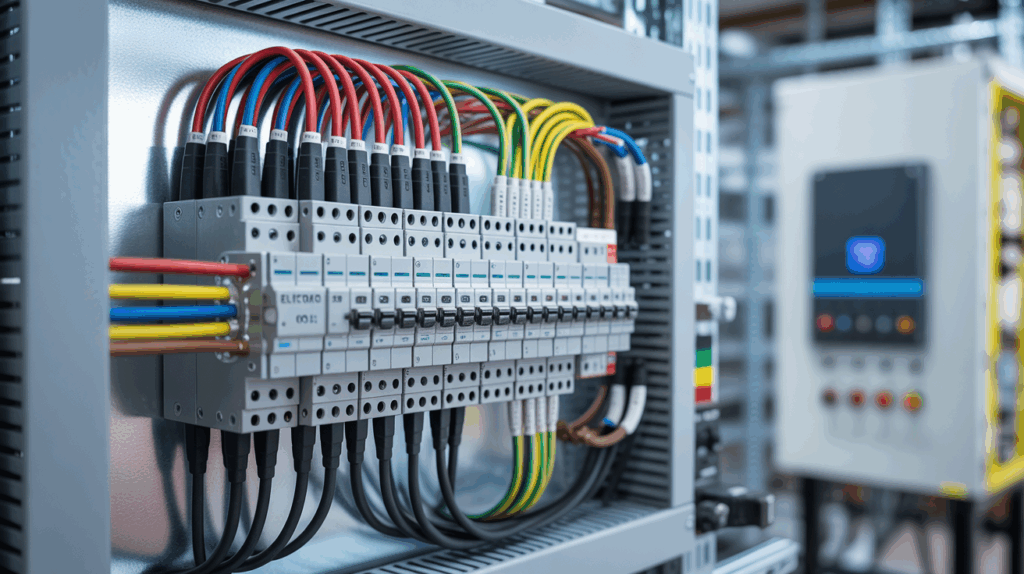

Design Considerations for Aluminum Busbars

When designing with aluminum busbars, engineers must account for factors such as:

- Current capacity – Ensuring the busbar can safely handle the electrical load.

- Thermal expansion – Aluminum expands more than copper when heated, requiring proper allowances in design.

- Connection points – Using compatible connectors to prevent galvanic corrosion between dissimilar metals.

- Surface treatment – Applying tin or silver plating for improved conductivity and corrosion resistance in certain environments.

Aluminum vs. Copper Busbars

While copper busbars have traditionally been the industry standard due to their higher conductivity, aluminum busbars offer compelling benefits for many applications:

- Lower weight and easier handling.

- Reduced material costs.

- Comparable performance in many low- to medium-voltage applications.

In projects where weight reduction and cost savings are top priorities, aluminum busbars are often the preferred choice.

Custom Aluminum Busbar Fabrication

At AP Precision Metals, we specialize in custom aluminum busbar fabrication to meet the exact specifications of your project. Our team can cut, bend, punch, and finish busbars to your requirements, ensuring optimal performance and seamless integration into your electrical systems.

We work with high-grade aluminum alloys and offer precision machining, plating, and finishing services to ensure durability and conductivity in demanding environments.

Why Choose AP Precision Metals

When it comes to aluminum busbars, precision and quality are critical. At AP Precision Metals, we provide:

- Expert engineering support for your busbar design.

- Advanced manufacturing capabilities for high-volume or custom orders.

- Strict quality control for consistent, reliable performance.

- Fast turnaround times to keep your project on schedule.

Get Your Custom Aluminum Busbars Today

Aluminum busbars offer a lightweight, cost-effective, and reliable solution for a wide range of electrical applications. Whether you need a standard design or a custom configuration, our team can deliver the precision and quality your project demands.

Contact us today to discuss your aluminum busbar needs and get a quote for your next project.